Product and Services

From aerospace to industrial applications, we deliver precision-cast aluminum components.

Aluminum casting is a highly accurate and efficient manufacturing process in which molten aluminum is poured into engineered molds to produce components that meet exact specifications. At M Castable, we utilize this advanced process to create complex, high-performance parts with outstanding surface quality and dimensional precision. Known for its lightweight nature, excellent corrosion resistance, and superior thermal conductivity, aluminum casting is ideal for demanding applications across industries such as automotive, aerospace, industrial machinery, and consumer electronics.

We offer a full suite of aluminum casting solutions designed to serve a wide range of customer needs. Our core capabilities include

- Die Casting – Ideal for high-volume production with excellent dimensional accuracy.

- Vacuum Die Casting – Produces stronger, cleaner parts by eliminating gas porosity.

- Investment Casting – Perfect for complex geometries and tight tolerances.

- Sand Casting – Versatile and cost-effective for low-to-medium volume production.

- Precision Machining – Ensures every component meets exact tolerances and finish requirements.

Each selected based on the specific performance, design, and production requirements of the project. These flexible techniques allow us to manufacture both intricate and large-scale components with consistency and quality.

Beyond casting, we provide precision machining services to ensure that each part is finished to exact tolerances and ready for critical use. Our custom coating services further enhance product durability, resistance, and visual appeal, adding an extra layer of functionality and protection to each component.

Our mission is simple yet powerful: to become the world’s trusted one-stop provider of aluminum casting solutions. Through a combination of advanced techniques, deep technical knowledge, and a commitment to excellence, we aim to deliver products that not only meet but exceed expectations—while building lasting partnerships grounded in quality and trust

Casting Methods We Offer

The sand casting process usually uses a pattern to make a hollow cavity in the sand, which is the shape of the finished part required. The pattern is generally made from wood or resin often with metal inserts to protect from abrasive wear.

The pattern itself is larger than the finished part as per parts shapes and thickness, to allow for the contraction of the metal during cooling. Patterns can be made using traditional manual pattern making skills or more often now, using 3D models through CAD/CAM to a CNC machine Additional tooling is usually needed to make cores, which are used to create undercuts, hollows or cavities within the final part itself.

In order to get the metal into the mould, a runner system is added to the pattern. It is designed to make sure once the metal has flowed through the down sprue, it will be filtered and its flow controlled to avoid turbulence whilst the mould is filled. Any thick sections can be chilled to promote accelerated solidification of material, by the addition of pieces of iron or steel, which preferentially cool where required. Risers are added to create reservoirs of molten metal to feed the casting, as it shrinks during the cooling/solidification stage.

Aluminium Gravity Die Casting is best suited to a higher volume of production, partly because the iron moulds – or dies – used in the gravity die casting process is more expensive to produce than the more typical wooden patterns involved in making sand castings. The benefit is the resulting accuracy of the casting produced from the Die, with it being possible to manufacture much more complex, finely detailed parts.

Gravity die aluminium casting, as the name suggests, uses the force of gravity to fill a mould – or, die – with a molten aluminium alloy. It is not just used for large-scale batch production, but also in cases where there is a particular need for the type of accuracy and consistency that sand casting cannot guarantee. Prototyping is often carried out using sand, but production will then move on to gravity die aluminium casting from there.

Gravity Die Casting gives a good finish to the surface of an aluminium casting and, although more expensive at the initial tooling stage, these early costs are off-set with larger batch production, as the unit cost obviously falls further as larger volumes are produced.

Typically a gravity die cast produced casting will require less finishing after the part has first been cast. Each component will require less finishing / fettling after the casting process further reducing the unit cost when compared to a sand cast component.

We can arrange for paint finishing, along with powder coating, anodising and polishing means that, as part of our commitment to a total solution, able to supply completely finished parts to your assembly line. Aluminium cast parts can be put through a number of pre-treatment processes to prepare them for paint finishing, with either powder coating or wet spraying techniques.

Powder coating produces a hard-wearing finish that is tougher than conventional paint and is often preferred for industrial products. Whichever paint finishing method you opt for; Foundry & Fabrication can ensure the best possible results for your aluminium casting using high-quality local sub-contract paint finishers.

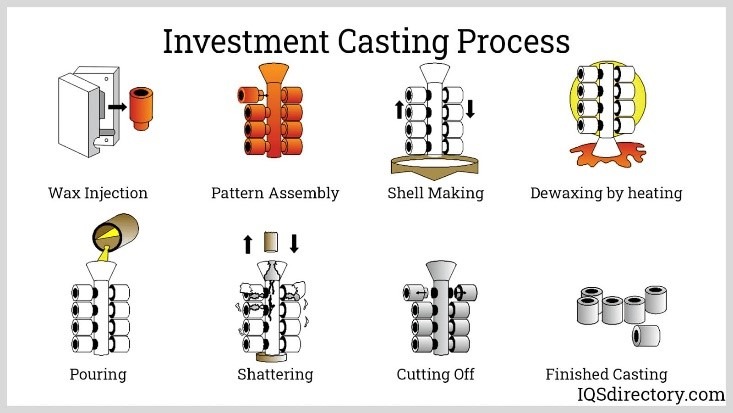

The process of investment castings is much complicated. A foundry uses this process for producing small intricate and metallurgical sound castings under close supervision.

The investment castings technique used in metal formation is also known as lost wax casting. It’s most common and oldest casting process technique used by every industry in India. The Investment Castings technique is widely used to bring high level of accuracy and integrity in alloys.

Foam casting is one of the most modern approaches of investment castings where you have to follow few steps to get final investment castings. Such manufacturing is comparatively more expensive than die casting and sand casting.

Anodising and chroming can be used to protect the surface of aluminium castings from subsequent corrosion, especially where corrosive elements such as seawater are common.

Polishing can be an important part of the finishing process for sand casting and can be arranged total solution for your aluminium casting needs.

Polishing can be required as part of an aesthetic or a surface finish requirement before a range of finishes can be offered.

Occasionally, to get the best results with aluminium casting, it is necessary to alter the physical properties of the metal alloys being used. Using heating and cooling processes, we can soften or harden the materials used in our aluminium foundry until they are suited to subsequent processing. Most often used to increase the strength of an alloy, it can also aid the machinability of the castings to improve finish machining tolerances.

Heat treating requires precise control over temperature to achieve the results, as it is important to make sure that the aluminium alloy remains within an exact temperature range for the correct length of time, and cools at the proper rate.

Experience Innovation: Explore Our Aluminum Castings Products

Expert professionals at Megha Enterprise offer Solutions right from the Die Design & manufacturing, Core manufacturing, Casting with GDC & LPDC processes, Non- Destructive Testing, Lab Testing. Heat treatment up to Shot Blasting and also provide special machining facility to final products.

By leveraging advanced technology, we ensure that our processes meet the highest standards of quality and performance, while also prioritizing safety, sustainability, and environmental responsibility.

Aviation Components

We provide high-performance aviation components made from aeroaluminum, designed for critical parts like engine housings, wing structures, and landing gear. More …

Engine Blocks & Components

Our precision-cast aluminum engine blocks and components are widely used in both automotive and industrial machinery. More…

Industrial Machinery Parts

We offer aluminum castings for machinery parts, including gearboxes, housings, and pumps. These components are built to withstand high-stress environments and deliver long-lasting reliability for industrial machinery.